Nanoplus is developing quantum cascade lasers (QCLs) for the MIRACLE project. These lasers will be used to determine the biochemical composition of joint cartilage. Such knowledge is very valuable and leads to a better diagnosis of osteoarthritis. The outcome of the MIRACLE project is a prototype, which assists the doctor to identify the extent of the knee damage due to osteoarthritis. QCLs are fabricated using epitaxy technique and depositing a specific sequence of III-V semiconductor materials on a wafer. In the process of the manufacturing lasers sources, materials such as InP, InGaAs or InAlAs are used.

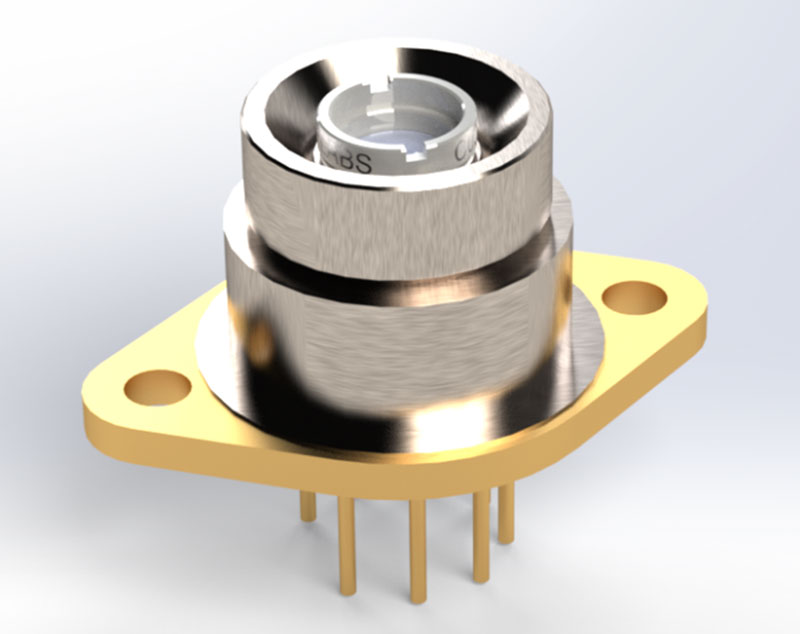

The tiny laser chip (in order of several hundred’s micrometre) must be installed in adequate packaging in order to be integrated into a macroscopic system. The choice of laser chip package is depending on application of the laser. Thus, in order to meet the requirements of the MIRACLE project, nanoplus has developed a packaging solution with a TO3 package and Lens-on-Cap configuration (s. Figure 1).

Figure 1. TO3 packaging with lens-on-cap configuration.

The right choice of the thermoelectric cooler and the lens are particularly important for the laser performance. The thermoelectric cooling element is needed to operate the laser at a specific temperature and to dissipate the heat generated. Moreover the lens is essential to ensure a collimated laser beam that can be coupled into a fiber or beam combiner.