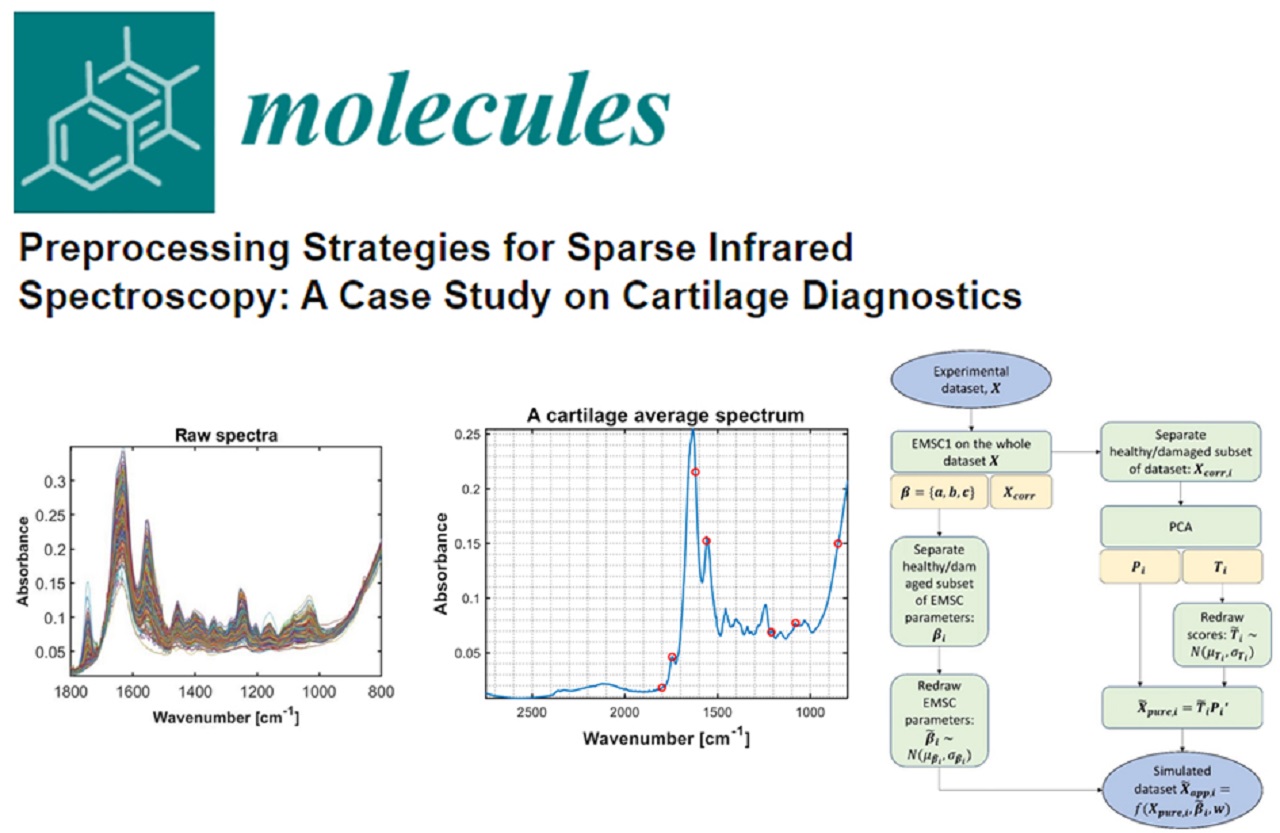

Special ATR probes for measurements in the MIRACLE project have to be bent for a successful operation using an arthroscopic instrument. The unique design of tiny parts has been developed to create a thin bent ATR Probe for this purpose.

Standard ATR probes are assembled with straight fibres which deliver the radiation to and out of the ATR sensitive element. The first prototype of the ATR probe for the MIRACLE project has been assembled with a mirror inside to direct the radiation into the ATR crystal at the end of the hook. However, it was found that the hook design with a bent tube is more reliable for the arthroscopy application. Bent InfraRed fibre can deliver the radiation effectively to the ATR crystal, and the number of inner tiny parts is significantly reduced. The first ATR arthroscopy probe with a bent hook is shown at Figure 1. Special techniques of the fibre bending, and positioning have been implemented to create this prototype. In total, two probes have been manufactured with different design, 90 degrees and 120 degrees hook at the probe shaft.

Figure 1. Two ATR probes with bent hook tip: a) 90 degrees bending, b) 120 degrees bending

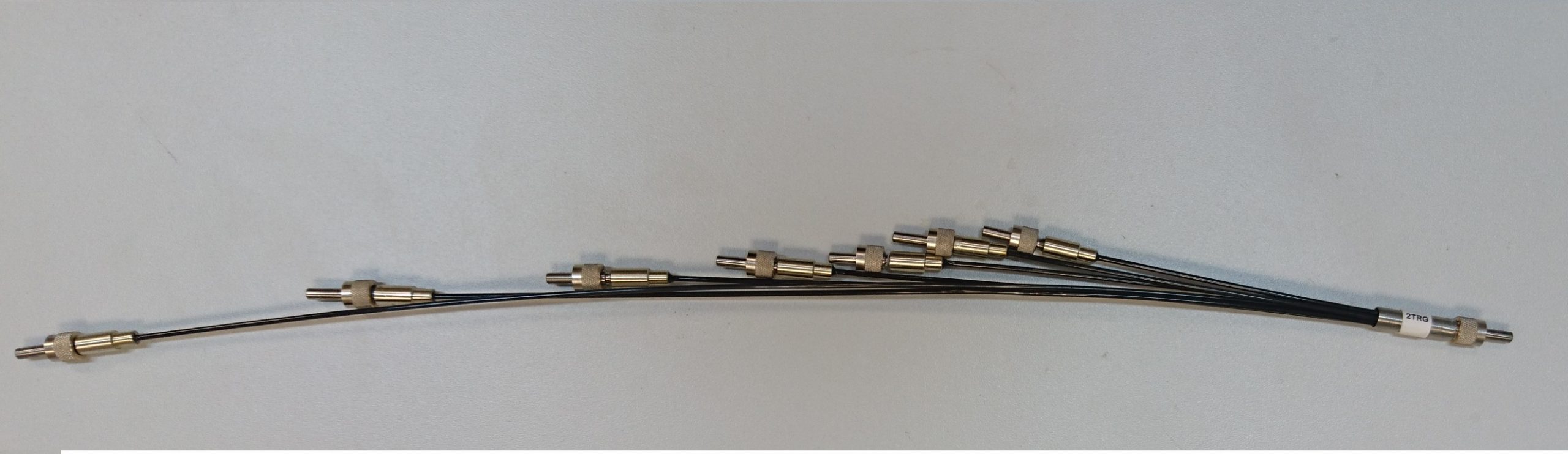

Both probes have been tested with FTIR spectrometer to make sure that the probes show the throughput in the entire spectral range of the MIRACLE project. A special IR-fibre bundle with 7 IR-fibres of minimal possible diameter has been build and successfully tested to couple all 7 x QCL into the fibre optic probe.

The bundle shown at Figure 2 exhibits a coupling efficiency close to the calculated value.

Figure 2. Fibre optic bundle coupler for 7 x QCL to the ATR fibre optic probe.